| All Product... |

Precision small steel belt

According to the

different requirements of users and the use environment, the standard flat

steel belt of NAUT, selects some specific raw materials and special processing

methods to weld the thin steel belt into a closed type form (W-Rolling, TIG-W, M-L-W,

M-P-W), and then through a series of pressing, leveling, grinding, heat

treatment and other methods, It makes the steel belt and the weld line flat and

smooth, and the overall tensile strength is high, so that it can meet the

transmission principle and the production process requirements of the end user.

According to the

different use needs, the steel belt have lots of model, It can be used in

almost all industrial fields of transmission and continuous process processing,

especially in the environment where the traditional industrial conveyor belt

can not work.

Steel Belt Advantage

Application

Grade of steel belt

Special stainless

steel

Model: ASS1200; ASS1000; MSS1650

Special Carbon steel

Model: CS1300

Special alloy steel

(under development)

For the first-time users, we suggest you contact our sales staff or engineers directly to get more information and help.

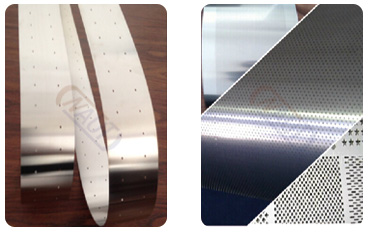

NAUT Perforated Steel Belt

Through a variety of

drilling methods and processes (mechanical and non mechanical), NAUT engineers

can make a variety of high-precision hole patterns on the steel belt:

NAUT Steel Belt

Specification

According to the requirements of different users, NAUT engineers adopt a variety of hole opening technologies to make both sides of the hole belt free of burr and smooth surface, and even less affect the overall flatness of the belt.

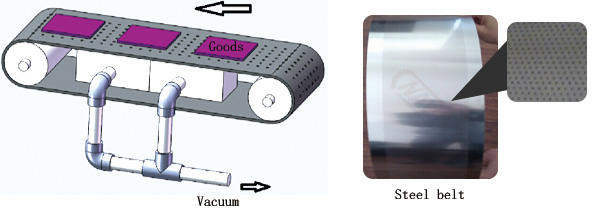

NAUT Synchronization Steel Belts

synchronous belt

NAUT offers synchronous belt are manufactured with precision perforation, Main materials is made of the stainless steel or carbon steel , we provide two types of single row hole and double row hole to customer requirements, these belts have more the applied to precision conveying and positing at a glance.

Metal synchronization belts can meet different environment requirements, metal synchronization belts has more advantages than traditional synchronous belt.The material of synchronous wheel is determined according to different working environment and requirements. The commonly used materials are stainless steel, aluminum and wear-resistant non-metallic materials. The pulley is mostly cylindrical and I-shaped. There are some regular convex teeth or grooves on the synchronous wheel, and their shapes are mostly semicircular and long waist.

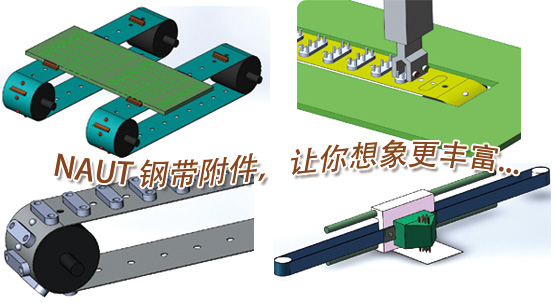

Spare Part

With the steel belt as the carrier, various components and devices can be installed on the steel belt to meet the more functional requirements. At present, in the automatic packaging production line and continuous assembly production line of medicine, food and electronic components, various forms of accessories are loaded on the steel belt, some for gear filling, and some for positioning assembly. The installation of all components must meet the bending operation conditions and anti tension limit of the steel belt

The steel belt can not only run independently, but also be used in combination (parallel and interweaved) to meet its requirements.

Application

Steel Belt Advantage

Coating Steel Belt

NAUT coating steel belts can be ring belts or open types belts, in order to meet different client’s requirement, we can make TEFLON heating coating, titanium coating, heating spraying thermal insulation.

Steel belt surface coating functions:

Enhance steel belt surface stickiness resistance

Enhance steel belt surface smooth resistance

Enhance steel belt surface thermal insulation

|

Coating type |

Purpose |

Temperature |

Thickness |

Colour |

|

TEFLON.TFE |

Anti adhesion |

Up to 350 ° C It can withstand 500 ℃ instantaneously |

0.03-0.08mm |

Green,

Black |

|

TEFLON.FEP |

Anti corrosion and low temperature resistance |

Up to 250℃ Low to -200℃

|

0.03-0.08mm |

Green,

Black |

|

TEFLON |

Food grade anti adhesion |

Highest 300℃ |

0.03-0.08mm |

Gray |

|

Titanium |

Anti corrosion and wear

resistance |

Temperature resistance of the same type of steel belt |

PVD |

Rose Gold |

|

ZrO₂ |

Wear resistance and high temperature resistance |

Highest 800℃ |

0.05-0.15mm |

Gray white |

Open type steel belt

The open type steel belt is also called the straight steel belt. After the steel belt is made to the required size, the fixed metal blocks are installed at both ends of the steel belt. Finally, the metal blocks with holes are bolted on the driving wheel hub with bolts. As the reciprocating transmission (discontinuous circular motion) in the equipment, the multi style structural design can meet the needs of more functions. The specially designed steel belt has the highest efficiency It can be used in 360 degree operation mode.

Characteristic